BGS Announces the Release of its Graphene-Enhanced Admixture for the Concrete Market

January 10th, 2023 – Toronto, Ontario, Bio Graphene Solutions (“BGS” or the “Company”), announced today the development of the Company’s first graphene-enhanced product for the concrete market.

Leveraging its capability of converting 100% organic materials into high-quality graphene via a patented cleantech process, BGS has developed a strength performance admixture for commercial concrete mix designs.

Developed primarily to tackle the removal of cement (the binding material in a concrete mix that also contributes to more than 8% of the global CO2 emissions due to its harmful manufacturing process), the Company’s graphene admixture can remove at least 15% of the cement content in concrete without sacrificing the compression strength performance of the overall concrete product. BGS believes its graphene-enhanced admixture is the only admixture product in the market that can facilitate the removal of cement utilizing graphene’s nanotechnology and still provide significant cost and CO2 savings to its potential customers in non-specialized commercial concrete mix designs (25MPa to 40MPa mixtures).

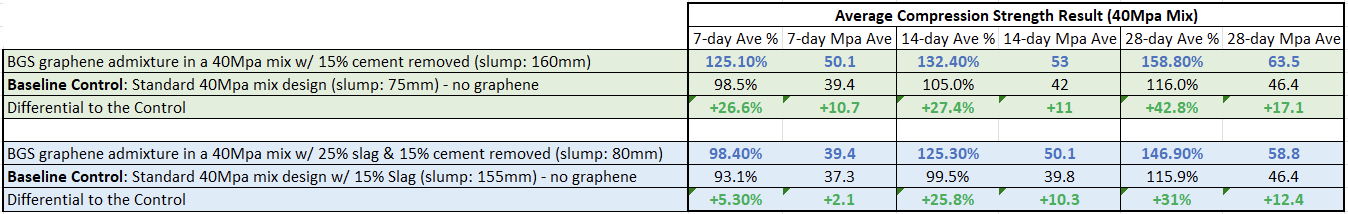

After conducting more than 3,000 compression strength tests, and a focus on a 40MPa concrete mix design (typically used for condominiums in creating external walls, slabs, structural pilings, and foundations), BGS observed the following with its graphene admixture:

• After removing 15% of the cement content, a 25% increase in strength gain as early as 7-days, and that strength gain maintained or increasing over a 28-day period (as shown in Table 1.1)

• After removing 15% of the cement content, the ability to enable a 40MPa mix design to behave like that of a 60MPa mix design after 28-days

• Significant strength performance synergies with supplementary cementitious materials (SCMs), like that of slag, even after removing 15% of the cement content in a 40MPa concrete mix

• Rapid strength gains even after removing 15% of the cement content – with 40MPa trials attaining strength performance results in 5-days (110% or 44MPa) that required 28-days for the control (no cement reduction) to achieve

• Acceptable workability rates (“slump” numbers) required for commercial use

• Replacing the need for a water reducer (admixtures designed to mimic the addition of water that is present in concrete mixtures to improve workability rates without compromising strength) further improving the cost savings of the overall concrete mix design

• Repeatability of its successful trial results

All concrete testing and data relating to the Company’s results was performed and verified by 3rd party certified concrete lab facilities in Ontario.

Dr. Laura Mammoliti, Head of Product Development – Concrete Products, commented “In my 15 years in the industry, this is the first time that I have worked with a product that can significantly reduce cementitious content

without sacrificing plastic properties of the mix itself while improving strength. I’m very excited to be at the ground level of this innovative solution to address the industry challenges related to the CO2 impact of concrete”.

Liam Farrell, Chief Operating Officer, commented “The carbon removal impact of our concrete graphene admixture is very meaningful and very measurable. According to the Portland Cement Association (PCA), the manufacturing of cement produces 0.9 pounds of CO2 for every pound of cement made. Our capability of removing 15% of the cement content in a 40MPa mix design is equivalent to removing 480kg of CO2 per truckload of concrete – at least 5 times more effective compared to the next leading carbon removal technology in the market. To put this into perspective, if we attained full product adoption in our local addressable market – looking just at Ontario alone – we believe this would be equivalent to over 200,000 metric tons of CO2 removed.”

Liam added, “Due to our extensive testing dataset and our ability to leverage in-house concrete expertise from people like Laura, we’ve been able to attract multinational organizations within the concrete market that are interested in learning more about the performance, cost, and environmental benefits of using our graphene admixture. These organizations are now engaged with BGS and are in active product development with the Company.”

BGS is also in the process of exploring carbon credit programs that reward innovative technologies that can reduce the use of cement and provide a measurable reduction in greenhouse gas (GHG) emissions. Market adoption of its graphene admixture would enable the Company to benefit greatly from the issuance and monetization of high-quality carbon credits and further solidify the Company as a sustainable thought-leader in the concrete market.