Technology

WHAT IS GRAPHENE

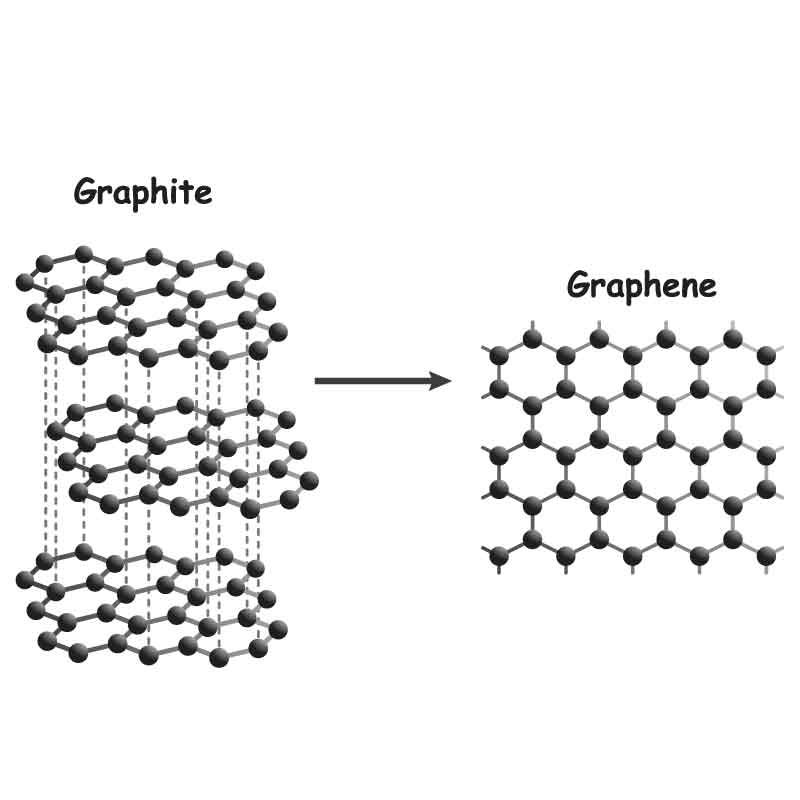

Graphene is derived from carbon. At its simplest and purest form, graphene is a 2D single-layer of carbon atoms arranged in a hexagonal lattice. It was first isolated by the University of Manchester in 2004 and won a Nobel prize as a material in 2010.

The most common way of producing graphene is by exfoliating graphite (a purer form of carbon – composed of 100,000s of carbon layers). Graphene is defined as 10 carbon-layers or less, and the properties gained from graphene as a performance additive, exponentially increase as the number of carbon layers diminish… therefore, the expectation of performance from integrating 2-layered graphene in a material would outweigh the performance benefit from that of 8-layered graphene.

As a performance additive, adding a trace amount of graphene can replace other additives in various commercial applications at a lower cost and superior quality – improving strength and/or making an application lighter as less raw material is needed for the same performance

Characteristics

of graphene

- Strength

- Toughness

- Elasticity

- Thermal and Electrical Conductivity

- Water Impermeability

- Weight Reduction

THE GREATEST CHALLENGE WITH TRADITIONAL GRAPHENE IS PRODUCT CONSISTENCY, COST-EFFICIENCY, AND ENVIRONMENTAL IMPACT

GRAPHENE’S CURRENT DRAWBACKS

Graphene’s applications are wide-ranging with the potential to disrupt numerous industry verticals. That said, there are significant drawbacks that currently exist in the traditional conversion of graphite-to-graphene via a liquid-mechanical exfoliation process:

- The graphene exfoliation process is not environmentally friendly – requires harsh chemicals, acids, and solvents that produce by-product waste

- The quality of the graphene is highly dependent on the quality (level of impurities) of the graphite source (due to batch-to-batch and purity inconsistencies in graphite deposits, traditional processes have difficulty in producing consistent graphene quality which leads to poor product confidence for end-customers)

- Requires a large operating facility to support commercial production

- Constrained source material supply-chain – graphite deposits mainly found in South America, Africa, and China

- Integration issues – poorer graphene quality creates stability problems with final product integration (for example, sand mixed with water vs. salt mixed with water)

- Overall poor carbon footprint to produce

THE BGS DIFFERENCE: PRODUCING A CONSISTENT, HIGH-QUALITY BIOGRAPHENE PRODUCT VIA 100% ORGANIC SOURCE MATERIALS

OUR NANOTECHNOLOGY

Our cleantech production approach is ecologically friendly and non-invasive, differing greatly from traditional graphite-based production methods.

- Unique IP that enables us to convert readily available 100% organic materials via a thermal-mechanical process

- Clean-technology production methodology – we do not rely on harsh chemicals, acids, or solvents during our production process (no by-product waste)

- The process is controllable – can be calibrated to produce different quality levels of biographene that’s BEST suited for different applications

- Compact and efficient production design – does not require a large industrial footprint to support commercial production

- Price leadership – The QUALITY and CONSISTENCY of our graphene material enables much lower graphene loading concentrations to achieve superior performance results – allowing us to support commodity driven applications in a cost-conscious manner

- The quality and purity of our material allows us to enter any relevant graphene market (e.g. batteries, coatings, thermoset, thermoplastics & electronics)

*BGS’ proprietary nanotechnology process is patent pending. USPTO # 63/365,739